We were recently contracted by an automation sector customer interested in building a ambitious two-tier weldment machine base for mounting automated equipment. We fulfilled this project need by taking our standard two-tier custom machine base and modifying it according to their specific design needs. The end solution was a unique combination of engineering and manufacturing efforts that was well received by the customer.

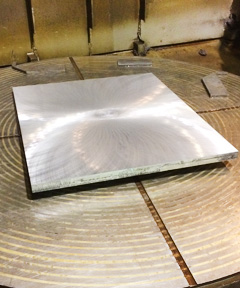

We manufactured the custom machine base through a series of cutting, welding, grinding, machining, and process painting steps on the build material specified, HR Steel. A 148” Blanchard rotary grinder, a continuous welding system, and shot blasting were used to perform primary manufacturing and surface treatments. Necessary surfaces and guides were ground down to 63 micro and confirmed by process inspections.

Due to our skill in heavy, demanding projects that require precise operation of sensitive grinding equipment, we were able to complete and deliver the completed two-tier machine base in only four weeks. The customer was pleased with every aspect of our work and is ready with more orders, reassured by our performance that we can deliver on difficult jobs without sacrifice.

To learn more about our services, see the table below or contact us directly.

Custom Large Grinding Specifications

- Product Description

Two Tier Custom Machine Base

- Capabilities Applied/ Processes

Primary: Cutting, Welding,

Secondary: Grinding, Machining, & Painting

- Equipment Used to Manufacture Part

148” Blanchard Rotary Grinder, Cont Welding, Shot Blasting

- Overall Part Dimensions

60 x 84 x 35-5/8

- Material Used

HR Steel

- Material Finish

63 Micro

- Industry for Use

Automation

- Volume

1

- Delivery/ Turnaround Time

4 weeks

- Delivery Location

Indiana

- Standards Met

Customer supplied print, 2D CAD Drawing

- Product Name

Two Tier Weldment

- Why did you choose this project to show case?

It shows that versatility of creating and manufacturing a Large weldment to our customer’s needs.